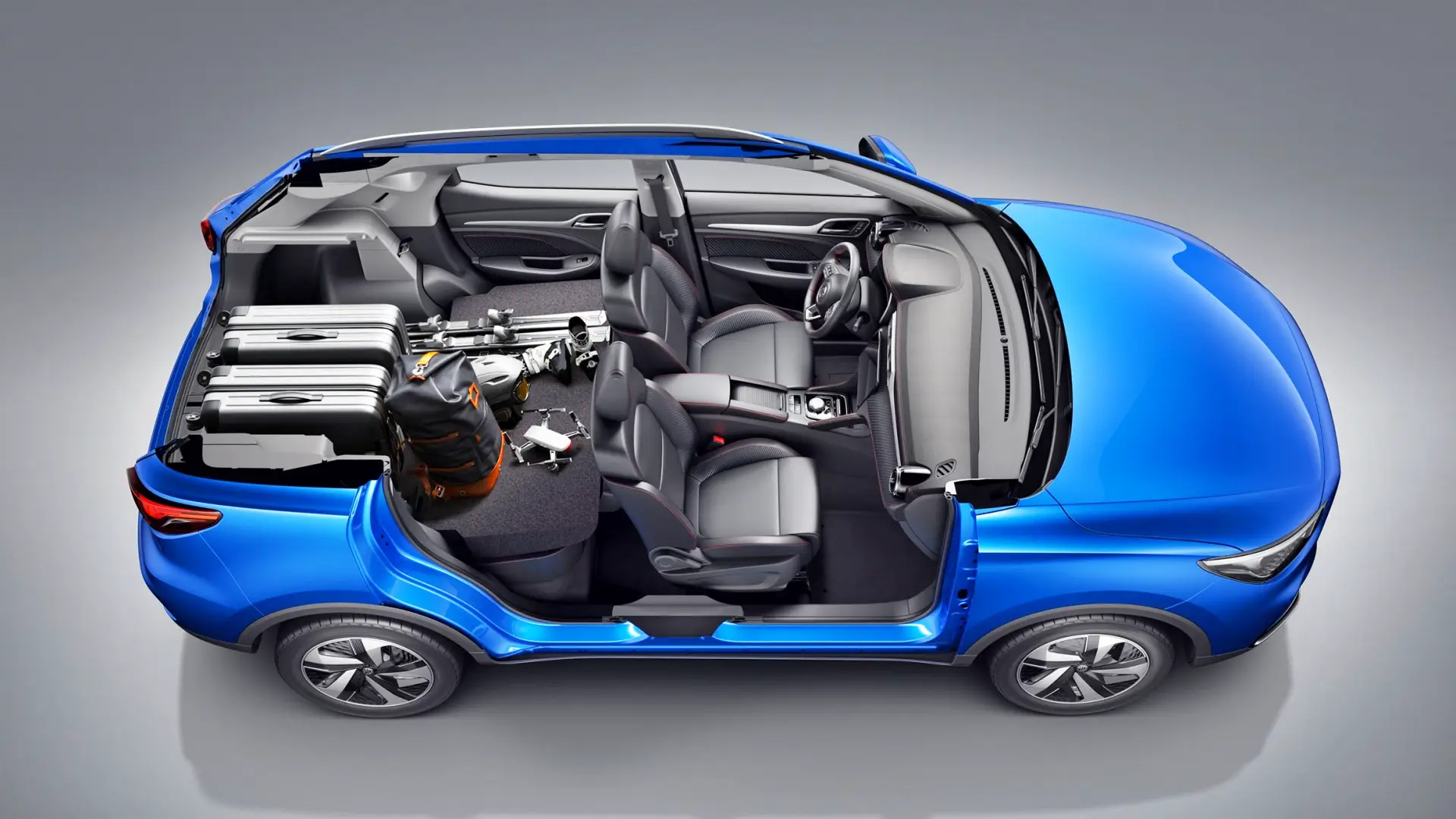

Volkswagen has officially confirmed that in 2026 it will begin manufacturing a high-volume electric SUV in Wolfsburg, Germany. This model will resume the commercial name Tiguan, although, from a technical point of view, it will not share any element with the thermal Tiguan, whose third generation was released last month.

To differentiate them from each other, the electric one could be named ID. Tiguan, giving continuity to the company’s current nomenclature system. It will be one of the first Volkswagen models based on the MEB+ modular platform, a profound evolution of the MEB that will debut in 2025 with the ID.2, the replacement for the Polo.

This new architecture will bring with it numerous improvements, including longer autonomy and efficiency optimized by 10%. In addition, charging times will also be reduced, going from the 35 minutes that a MEB-based model needs to recover 70% of its range (10-80%) to just 21 minutes. Of course, a 400-volt system will continue to be used.

Located immediately below ID.4, ID. Tiguan is probably around 4.40 meters long, constituting itself a direct rival for the KIA e-Niro and Renault Scénic E-TECH. As will happen with ID.2, ID. Tiguan will distance itself from the current design language of the ID range, opting for more classic lines that are closer to the company’s thermal models.

Volkswagen will also manufacture the electric Golf in Wolfsburg, which will hit the market in 2028

Volkswagen also plans to start manufacturing the ID.3 in Wolfsburg (it is currently assembled in Dresden and Zwickau), which will be replaced in 2028 by the ninth-generation Golf, which will be exclusively electric. Unlike the ID. Tiguan, the ID. Golf will use the SSP platform, a new-generation architecture equipped with an 800-volt system. The ID. Golf will have a brother from CUPRA, although it is not yet clear if it will be called Born or León.

“We are taking the transition to electromobility as an opportunity to reduce the complexity of our production operations and further increase the efficiency of our plants. “We are systematically grouping vehicles based on the same architecture of all brands in our plants,” explains Christian Vollmer, head of production at Volkswagen.

«In this way, we will save important investments in the integration of different vehicle architectures. Rather, we want our plants to produce several different models based technically on the same architecture.