Volkswagen will end the decade with six gigafactories mass-producing batteries for its range of electric vehicles, and that’s in Europe alone. For this, it has signed strategic agreements with three companies in the sector, starting with the raw material: lithium. The supplier Vulcan Energy will supply the white gold to Volkswagen starting in 2026, with the details of the contract being confidential. The agreement is for five years but is defined as “long-term. “

This supplier uses geothermal energy to be able to simultaneously produce energy and lithium without carbon emissions, taking advantage of the underground heat and the particular groundwater of the Upper Rhine Valley area. It is the largest natural resource of lithium in Europe, and Vulcan ensures that it does not take fossil energy nor large areas to evaporate the water.

Both Renault and Stellantis have signed supply agreements for 2026 onwards with Vulcan Energy. The French have signed a deal of 26,000 to 32,000 tonnes a year, while Stellantis will need significantly more, 81,000 to 99,000 tonnes a year. Probably the request of Volkswagen is even bigger, as its position in the European market is ahead of Stellantis, despite the Sorpasso timely October.

Volkswagen wants to control the entire battery value chain

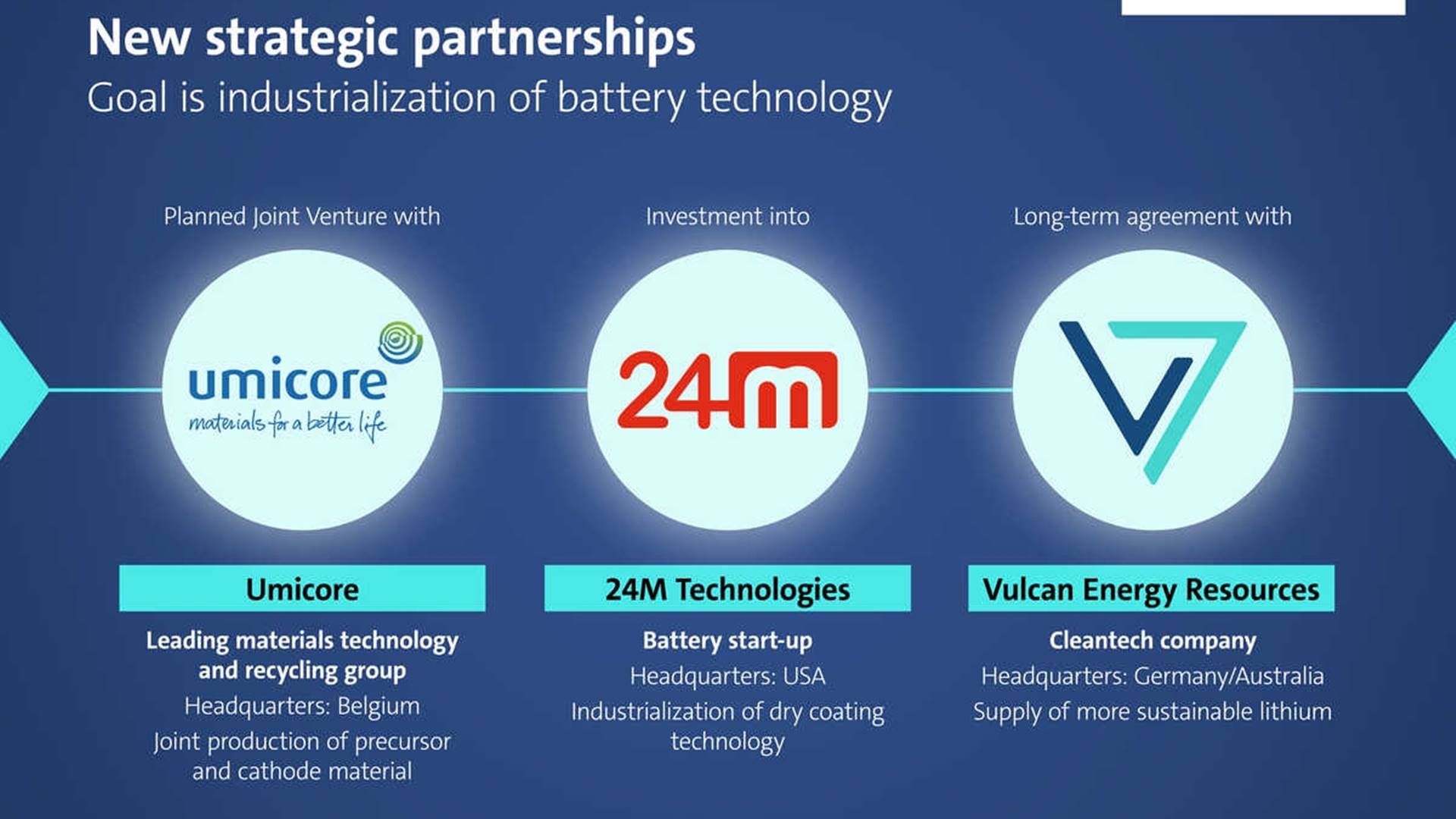

Obtaining lithium is the first step, mining. In the second step of the value chain, we have the necessary materials to compose the cells, the electrochemistry. Here comes the agreement signed with Umicore, both companies will form a joint venture – joint-venture – for the production of components such as precursors and cathodes.

From there we go to the third step, battery cell production. The initial production capacity of the JV will be 20 GWh of cells for the Volkswagen battery plant in Salzgitter (Germany). By the end of the decade, Volkswagen expects a cell production of 160 GWh per year, enough to equip more than 2.2 million electric vehicles.

The third agreement signed is with the company 24M Technologies, which will receive investment from Volkswagen. This company improves the dry coating technique, which prevents corrosion, cell deterioration, and false contacts. It is the SemiSolid ™ lithium technology, which they claim reduces the costs of batteries – optimizing their production – while improving their safety, reliability, and performance.

The fourth step is car manufacturing. Volkswagen currently has two factories dedicated exclusively to the production of 100% electric vehicles, Dresden and Zwickau, in addition to those that produce plug-in hybrids, such as Wolfsburg or Martorell. Volkswagen will gradually retire its mixed platform product ranges and factories will adapt to exclusively producing electric models.

And what about recycling? It is the fifth and final step, which closes the value chain and turns it into a closed cycle, or as Mufasa would say, the life cycle [of batteries]. In a later stage of the collaboration with Umicore, this aspect could be implemented for the recovery of cells out of use to re-obtain materials for new cells. On the other hand, the collaboration with 24M also encompasses more efficient recycling.

In a relatively short time, Volkswagen goes from being a manufacturer that depends on third parties to develop electromobility, to being one that cooks it and eats it almost everything on its own, delegating all cell production to one of its divisions and reducing its dependence on external companies. Right now he is halfway there.